Autonomous and Intelligent Aircraft Maintenance

Using the AR/MR technology with AI algorithms, our work supported reliability and maintainability of aviation assets that directly reduces life cycle costs by augmenting or replacing manual operations. Our technology is specifically for the aircraft maintenance community to perform functions such as material inspection, non-destructive inspection, coatings inspection and repair, and training. A specific need exists in the maintenance, inspection, and repair of special coatings that require precision, where the current methods are manual. The Navy also sought the development of an AI system to map out damaged areas such as in corrosion maintenance, repair by removing precise layers of coating and then reapply precise layers of coating, and catalog historical data. Autonomous or intelligent "smart" technologies have the potential to give artisan capabilities to intermediate or field-level aircraft maintainers, while utilizing AR/VR to develop autonomous robots.

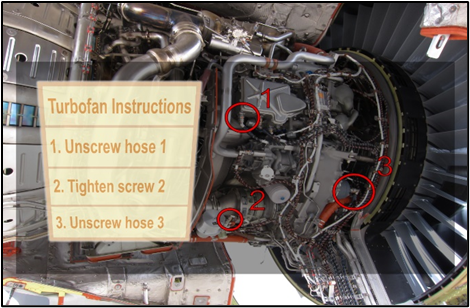

Our solutions enhanced the capabilities of aircraft maintainers by providing more natural, intuitive, and hand-free instruction, strengthening the physical design characteristics and security to meet rigorous DoD requirements. Our solution improved the capabilities of current aircraft maintenance personnel and provided accelerated and flexible remote training for new personnel. Aircraft maintenance tasks this will support include cleaning, coating removal, non-destructive inspection, and corrosion assessment. In addition, we created 3D virtual training using markerless SLAM.

Contact Us

Have a question? We'd love to hear from you.